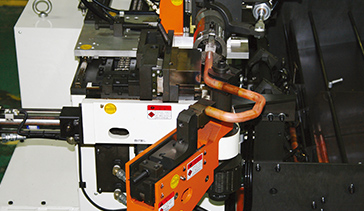

Fuso Industries Ltd. has a replete stock of molds and jigs to cast pipes from diameters of 4.76 mm up to 83 mm. The subtle margins of deviation between pipe and mold dimensions are adjusted by our highly skilled technicians, and our state-of-the-art automated facilities conduct production with high efficiency. The capabilities of our facilities allow us to engage in a wide range of pipe bending and parts processing.

Pipe Processing Technology

Pipe Processing

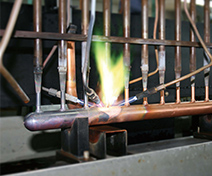

Brazing

The brazing process that binds pipes is performed with burners by our certified technicians for small volume orders, and by our state-of-the-art automated facilities for mass production orders. We braze not only copper pipes, but also steel, aluminum, and brass, among other metals. We manufacture high precision products utilizing multifarious brazing methods.

Technological Development

Improving low efficiency production processes

Fuso Industries Ltd. has a history of proactive development of proprietary machinery in order to improve the bottlenecks in our production processes. As a result, our production efficiency has skyrocketed, costs have been greatly reduced, and production schedules have been drastically shortened.

Automating highly skilled processes

It is unacceptable for products to manifest variations in quality due to the skill of the technician involved. Fuso Industries Ltd. is able to manufacture products at consistently high levels of quality by automating the processes that can only be performed by highly skilled technicians, such as wide-diameter pipe brazing.

Environment-friendly manufacturing

Environmental issues are front and center around the world, and Fuso Industries has been aggressively pursuing new production methods that do not utilize the hazardous substances defined by the European Union (EU) in the Restriction of Hazardous Substances Directive (RoHS) that was published in 2002. We have thoroughly inspected the substances utilized in our production line step-by-step and replace, recycle, and reuse wherever and whenever possible. As a result, we were certified under ISO 14001 environmental management standards in 2005.